Since opening a factory in Thailand in 2020, Kingtent Electronics (Kingtent) has been providing customers with comprehensive services primarily on PCBA assembly and precision electronic component testing. We provide a comprehensive service from material delivery, production, start-up, assembly, testing and commercial delivery. and solve various production-related problems at the customer’s process, and respond quickly and provide relevant support for the operation of customer assets. Highly trusted by customers The factory is based on quality. of Japanese system manufacturing and Chinese speed, its core is to contribute to the sustainable development of customers in the global electronics industry and deliver high-quality and cost-effective products.

We support from the design of the printing circuit sheet. To production, inspection, which helps reduce the time and cost of production

We promote effective production. With mainly considering the efficiency of production and quality

We provide assistance to solve various problems from the process of developing and experimenting with the production of printing circuits. To large quantities of production procedures Including various suggestions

Providing production services such as household electrical appliances, electronic components, automotive parts (Rice cooker, air conditioning, refrigerator, TV, etc.)

Providing quality inspection services (Size and external characteristics) Electronic work, automotive parts

Provide design and packaging services, and deliver work in accordance with the customer's order.

We provide work quality inspection services. And production related to electronic circuit panels For industrial machinery, automotive parts, household electrical appliances, electronic components

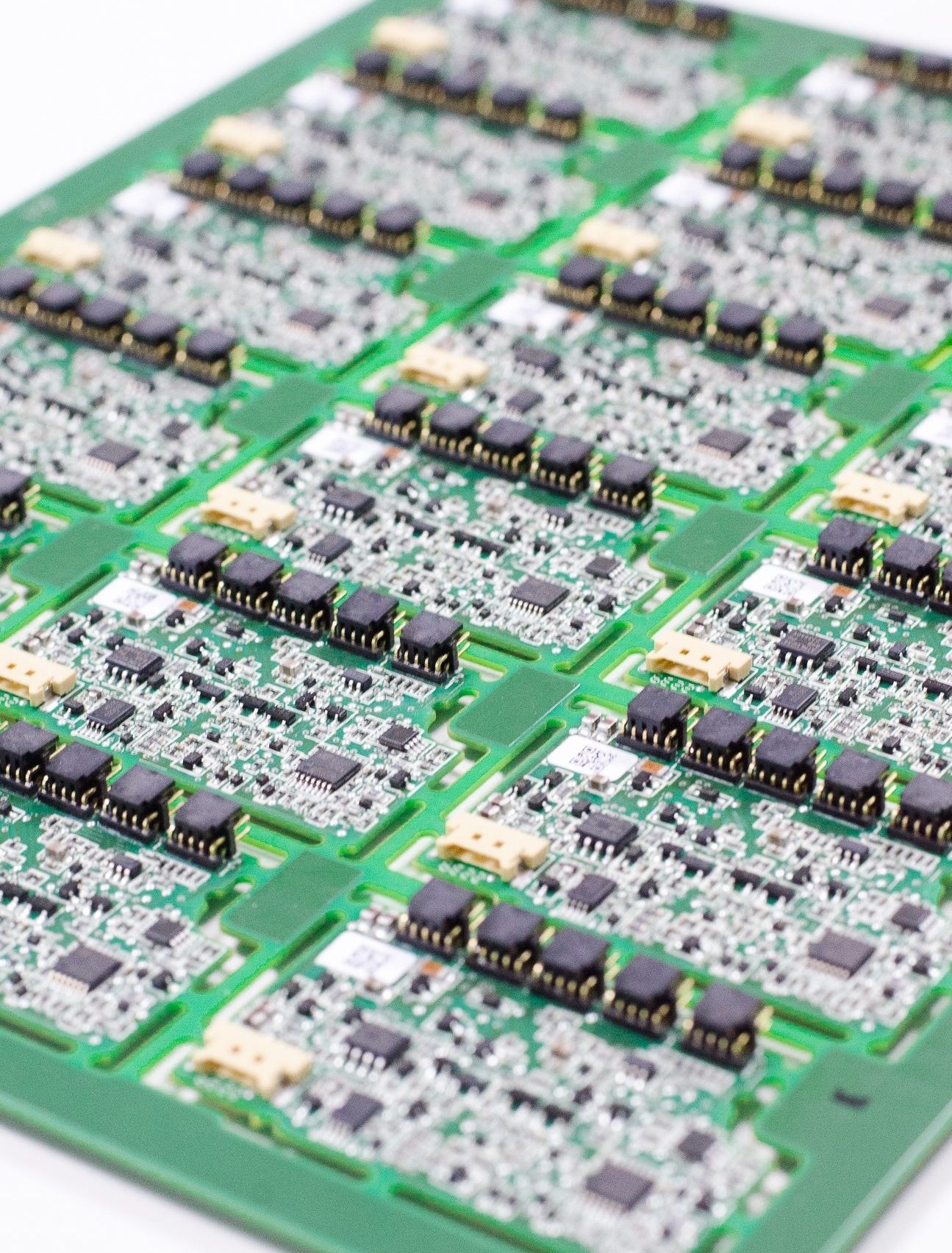

PCB ceramic, PCB Aluminum, flexible PCB (FPC), MultiLayer PCB, PCB large, PHENOLIC PAPER PCB etc.

Lead free alloys (Lead Free with AG mixed), lead -free alloys (Lead Free without AG)

【The narrowest part spreads】 | 0.3 mm |

【The accuracy of the part】 | +/-30um |

【Size of the smallest part】 | 0402 |

【Parts that support production】 | BGA、SOP、QFP、LED、QFN、etc. |

【The size of the part that can support】 | The largest : 360 mm x 410 mm. Thickness of PCB : 0.5 mm – 1.6 mm (highest: 5.0 mm) |

【Production methods that can be supported】 | SMT using lead and adhesive bonding |

We have machinery to support the production of many types of electronic circuits.

SMT | 16 LINE |

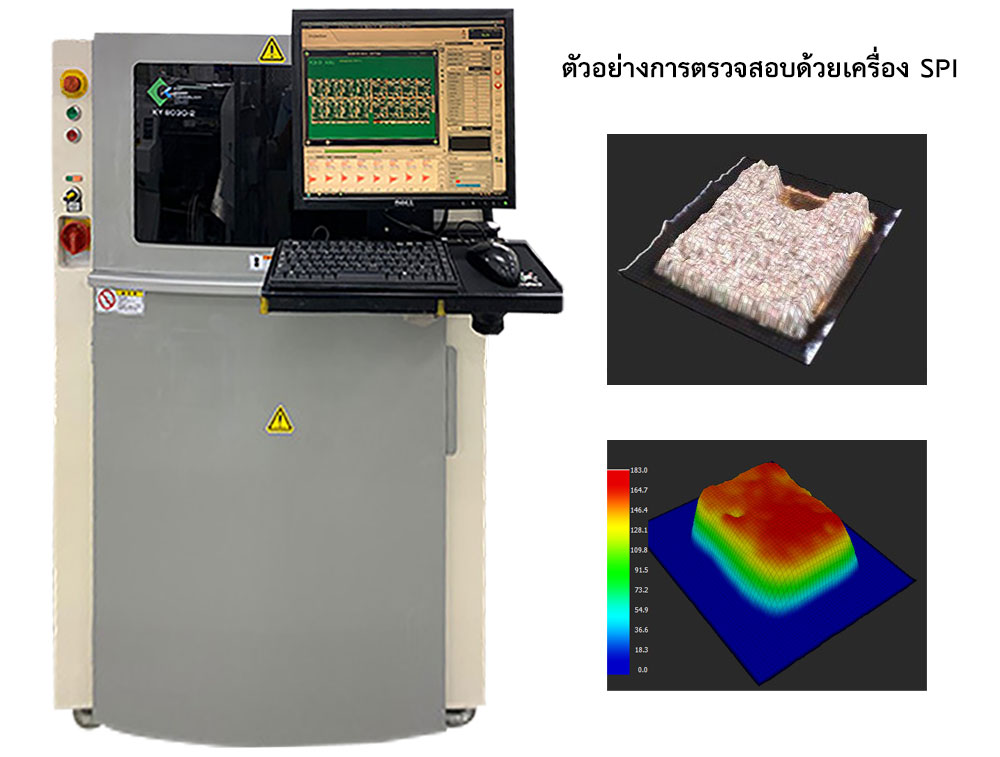

SPI | 16 machine |

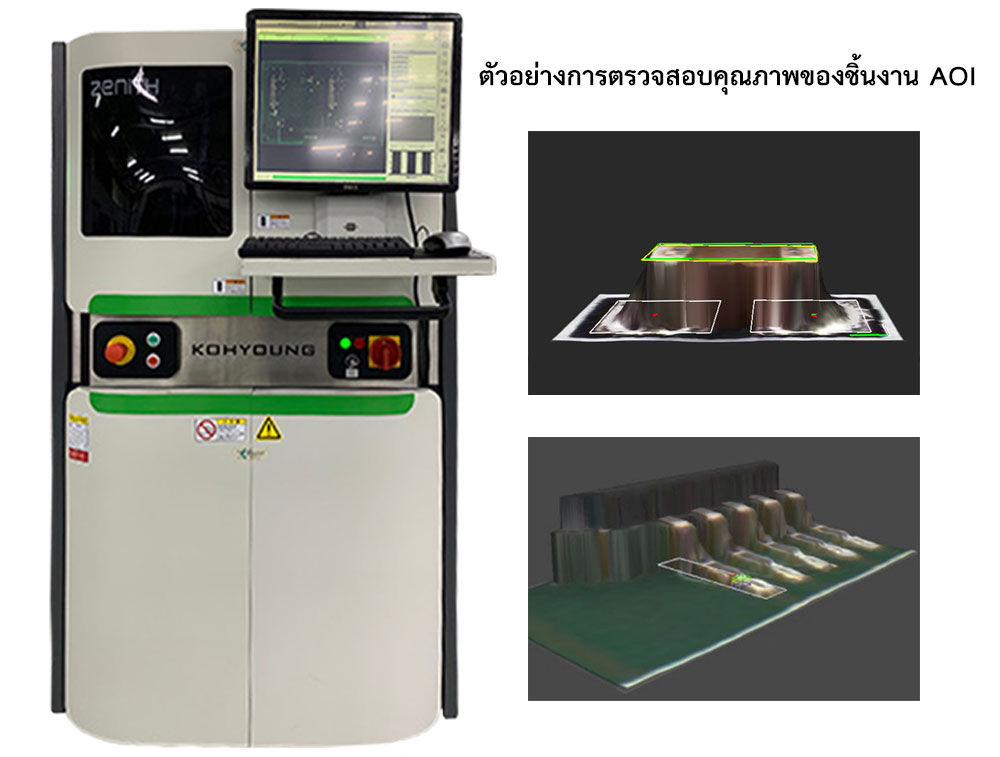

AOI | 16 machine |

X-Ray | 1 machine |

N1 | 1 machine |

Wave Soldering | 1 machine |

ICT | 7 machine |

Cutting PCB | 10 machine |

We manage various systems that make quality development. And production to enable the production of quality of Japanese standards for a long time Including production in Thailand as well According to the example to recommend as follows

We respond to customers’ needs. From production development and testing Until the large quantities of electronic parts Electronic device And the installation of printing circuit sheets

We will recommend services related to our production. In addition, please do not hesitate to contact us because we may be able to manage.

Coordinating PB-Free Solder (with Ag) PB-Free Solder (without ag)

Providing complete service, from the design of the circuit to ready made products